In sectors such as food, cosmetics, chemicals, and pharmaceuticals, having reliable, high-performance industrial equipment is crucial to ensuring quality, safety, and productivity. An industrial vacuum machine is a fundamental element in these environments, as it allows for process optimization by extracting air and gases from different systems.

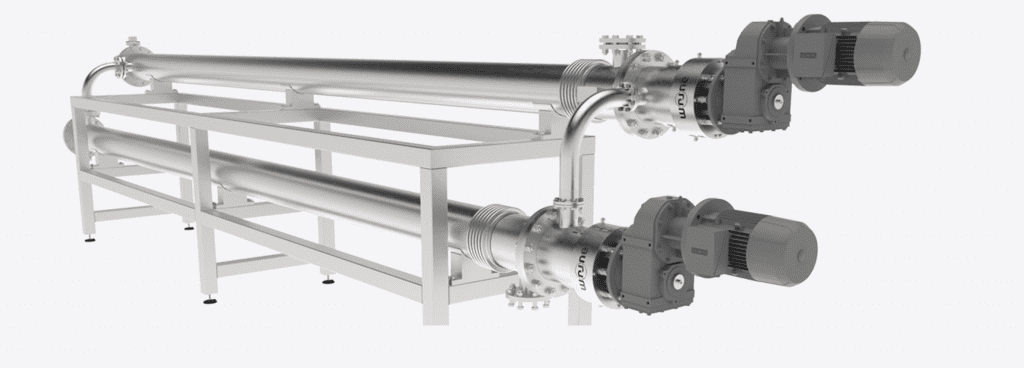

Aurum Process, a company specializing in industrial process solutions, offers custom-designed equipment with proprietary technology. Their machines stand out for their ability to adapt to each customer’s needs and for a clear philosophy: your process, your product, your future.

What is an Industrial Vacuum Machine?

An industrial vacuum machine is a device designed to create low-pressure conditions within a closed system. By extracting air and other gases, it enables processes such as:

- Vacuum packaging of food or pharmaceutical products

- Deaeration of liquids and emulsions

- Drying and dehydration in intermediate stages

- Safe transfer of sensitive liquids

With this technology, companies improve product stability, extend shelf life, and ensure higher quality standards.

Benefits of an Industrial Vacuum Machine

Implementing an industrial vacuum machine in your production processes offers tangible advantages:

- Increased Product Shelf Life: By reducing oxygen presence, oxidation and microorganism growth are prevented.

- Improved Quality and Consistency: In sauces, syrups, or emulsions, removing air bubbles ensures a uniform texture.

- Safety and Hygiene: Machines designed to meet the highest standards of the food and pharmaceutical industries.

- Process Optimization: Speeds up mixing, filling, and packaging operations, reducing production time.

- Energy Efficiency: Modern designs minimize consumption without compromising performance.

- Production Line Integration: Easy connection with homogenizers, reactors, or CIP systems.

- Cost Reduction: Fewer losses and more efficient use of raw materials.

- Specialized Technical Support: Aurum Process provides support from design to commissioning.

Why Choose Aurum Process as Your Industrial Vacuum Machine Provider

- Experience and Proprietary Technology

Aurum Process develops equipment with patented technology and global experience, ensuring innovative and reliable solutions. - Custom Design

Each machine is tailored to the plant’s requirements: capacity, format, product conditions, or industry regulations. - International Coverage

With projects in multiple countries, the company ensures technical support and applied knowledge across various industries. - Complete Integration

Beyond the industrial vacuum machine, Aurum Process offers complete systems that include homogenization, reactors, heat exchangers, and cleaning systems. - Future Vision

Their motto, “Designed for you: process, product, and future,” reflects a commitment to innovation and sustainable growth for their clients.

Practical Applications of the Industrial Vacuum Machine

- Food Industry

Vacuum packaging extends the freshness and shelf life of sensitive foods, while deaeration in liquids prevents defects in sauces, juices, and creams. - Pharmaceutical and Biotechnology Sectors

Air removal ensures sterility and stability of formulas, crucial in medications and supplements. - Cosmetics and Chemicals

In emulsions and personal care products, an industrial vacuum machine ensures homogeneous textures and the absence of imperfections. - Integrated Industrial Processes

In aseptic cooking lines or plant extraction, the vacuum stage is key to meeting safety and quality standards.

Conclusion

An industrial vacuum machine is not just equipment but a strategic investment that impacts efficiency, safety, and competitiveness in any production process.

With Aurum Process, companies gain access to custom-designed solutions, proprietary technology, complete integration, and specialized technical support.

👉 Want to optimize your production line with an industrial vacuum machine? Contact Aurum Process and discover how their experience and vision can drive your business into the future.