Industrial grinding is a key process in the transformation of raw materials across diverse sectors such as food, chemicals, mining, biotechnology, and pharmaceuticals. It involves the controlled reduction of solid particle sizes using specialized equipment, known as industrial mills, ensuring uniformity, efficiency, and quality in production.

In this article, we will explore in-depth what industrial grinding is, the types of equipment available, the benefits modern solutions offer, how to select the right system, and the trends shaping the future of this technology. Additionally, you’ll learn how Aurum Process has positioned itself as a leader in the design and manufacture of grinding equipment tailored to the specific needs of each client.

What is Industrial Grinding?

Industrial grinding is the process of reducing the size of solid particles to specific granulometries in order to enhance physical properties, facilitate mixing, increase solubility, or prepare materials for subsequent stages of production.

Depending on the sector, it can serve various objectives:

- Food and Beverages: Improve the texture and bioavailability of ingredients.

- Chemical Industry: Increase the reactivity and uniformity of compounds.

- Pharmaceutical and Biotechnology: Ensure homogeneity and purity in formulations.

- Mining and Materials: Optimize the extraction and processing of minerals.

Grinding can be performed either dry or wet, depending on the process requirements and the final product.

Types of Industrial Grinding Equipment

There is no one-size-fits-all solution in industrial grinding. Each process requires equipment tailored to the material’s nature, production capacity, and operational conditions. The main types of grinding equipment include:

- Blade or Hammer Mills

Ideal for dry grinding of fragile materials. These mills use impact and cutting to reduce particle size. - Ball Mills

Widely used in mining and ceramics. The friction and impact of spheres allow for fine and uniform granulometries. - Colloid Mills

Specializing in wet grinding of suspensions and emulsions, these mills ensure homogeneity and high stability in liquid or semi-solid products. - Disc and Roller Mills

Effective for medium-hard products, with adjustable pressure and distance settings to control particle size. - High-Energy Mills

Designed for advanced applications requiring ultra-fine grinding or nanoparticle production.

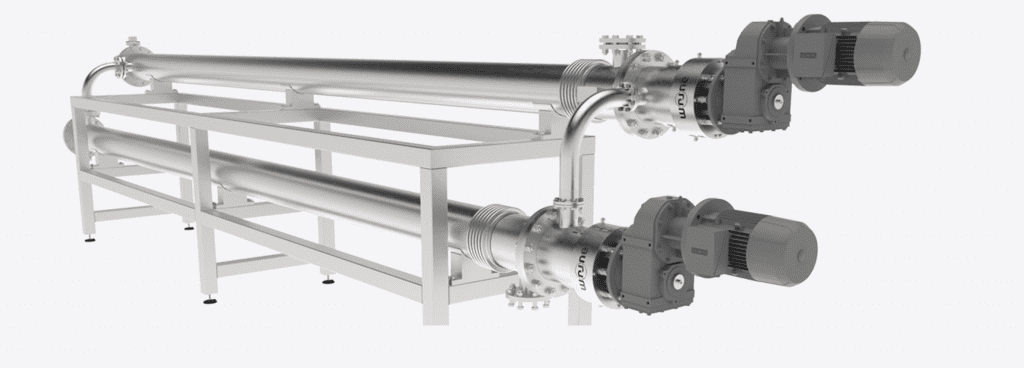

At Aurum Process, the engineer-to-order philosophy ensures that each piece of equipment is designed and built specifically for each customer’s needs, integrating optimally into their production line.

Benefits of Modern Industrial Grinding Systems

Technological advancements have transformed grinding into a more precise, efficient, and adaptable operation. The main benefits include:

- Energy Efficiency: Reduced energy consumption thanks to optimized designs.

- Particle Uniformity: Greater quality control of the final product.

- Versatility: Capability to process dry, wet, or pasty materials.

- Scalability: From pilot plants to large-scale production.

- Integration in Processes: Easy connection with reactors, homogenizers, and CIP cleaning systems.

- Simplified Maintenance: Accessibility of components and ease of cleaning.

- Cost Reduction: Less waste and higher raw material yield.

Factors to Consider When Choosing Grinding Equipment

Selecting the right industrial grinding machine requires analyzing several critical variables:

- Material Nature: Hardness, moisture, viscosity, thermal sensitivity.

- Desired Particle Size: From coarse grinding to nanoparticles.

- Production Capacity: kg/hour or tons/day, depending on demand.

- Process Conditions: Dry or wet grinding.

- Hygiene and Regulations: GMP, FDA, and specific certifications.

- Ease of Integration: Compatibility with existing equipment in the plant.

- Total Cost of Ownership: Not just the initial investment, but also operation, maintenance, and durability.

At Aurum Process, these factors are analyzed on a personalized basis to ensure the best solution for each client.

Industrial Applications of Grinding

Industrial grinding has applications across many sectors:

- Food Industry: Grinding of cereals, spices, cocoa, sugars, or functional additives.

- Pharmaceutical Industry: Reduction of active ingredients and formulation of excipients.

- Chemical Industry: Production of pigments, polymers, or catalytic compounds.

- Mining and Materials: Grinding of minerals, metals, and ceramics.

- Cosmetics Industry: Production of emulsions and micronized powders.

Emerging Trends and Technologies in Industrial Grinding

The future of industrial grinding is marked by technological innovation. Key trends include:

- Nanogrinding: Development of equipment capable of achieving nanometric particle sizes.

- Digitalization and Intelligent Control: Integration of sensors and software to monitor granulometry in real-time.

- Sustainability: Reduction in energy consumption and utilization of by-products.

- Hygienic Design: Equipment increasingly adapted to regulated environments, with automatic cleaning and high-quality materials.

- Modular Integration: Grinding machines as part of complete processing lines.

Aurum Process is at the forefront of these trends, incorporating innovation and customization into every project.

Conclusion

Industrial grinding is an essential process for transforming materials and ensuring quality across multiple sectors. Having the right equipment makes a significant difference in terms of efficiency, productivity, and competitiveness.

Aurum Process offers grinding solutions tailored to each need, with proprietary technology, custom design, and integration into complete lines. With a focus on innovation and experience, the company has become a strategic ally for businesses looking to optimize their industrial processes.

Want to learn how an industrial grinding solution can boost your business? Contact Aurum Process and discover equipment designed for your process, your product, and your future.