Brewer’s spent grain (BSG), commonly known as beer pomace, is one of the most common waste products generated during the beer brewing process. However, far from being just waste, this brewing by-product has great potential to be utilized in various industries. Thanks to plant-based extraction technology offered by Aurum Process, brewer’s spent grain is transformed into a valuable resource that can be turned into functional ingredients, animal feed, biofuels, and more. In this article, we explore how this waste can be effectively and sustainably utilized, contributing to the circular economy and industrial sustainability.

What is Brewer’s Spent Grain and How is it Generated?

Brewer’s spent grain is the solid residue left after the extraction of sugars and other components during the mashing of grain in the beer brewing process. This brewing by-product contains a large amount of fiber, protein, carbohydrates, minerals, and bioactive compounds, making it ideal for reuse in various applications.

Breweries generate large volumes of spent grain during beer production, and traditionally this waste has been discarded or used in animal feed. However, with the adoption of advanced processing technologies, it is possible to extract value-added components from this waste that can be utilized by various industries.

The Potential of Brewer’s Spent Grain in the Circular Economy

Valorizing brewer’s spent grain is one of the key solutions in the concept of the circular economy. Rather than being considered waste to be discarded, spent grain is transformed into a resource that can be reused across different industrial sectors. This approach not only reduces waste but also minimizes the environmental impact of breweries and promotes sustainability.

The circular economy aims to close the product lifecycle by maximizing resource reuse and minimizing waste. By utilizing spent grain, breweries actively contribute to reducing their ecological footprint and supporting the transition toward more sustainable production.

Technological Solutions for Valorizing Brewer’s Spent Grain

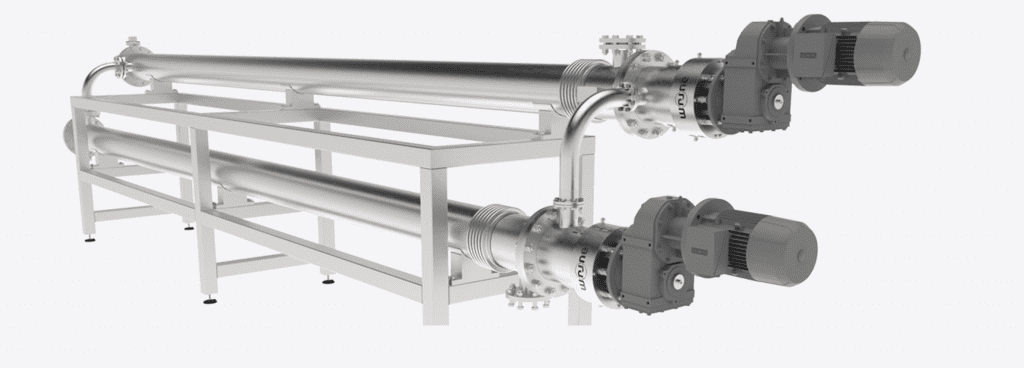

Aurum Process offers advanced plant-based extraction solutions that enable the full utilization of nutrients and compounds present in brewer’s spent grain. Through an innovative industrial process, brewing waste is transformed into functional ingredients that can be used in various applications:

- Animal Feed

Brewer’s spent grain is a rich source of fiber and protein, making it an ideal ingredient for animal feed. When properly processed, it can be used in the formulation of feed for livestock, poultry, and other animals, contributing to more sustainable feeding practices. - Functional Ingredients and Nutraceuticals

By extracting bioactive components, brewer’s spent grain can be converted into functional ingredients for the food industry and the manufacture of nutraceutical supplements. These substances can offer health benefits such as improving the digestive system and reducing cholesterol. - Biofuels and Energy

Brewer’s spent grain has a high energy content, making it suitable for use as a biofuel. By harnessing this waste in the production of biogas or solid biofuels, energy can be generated sustainably. - Cosmetics and Personal Care Products

Components of brewer’s spent grain, such as antioxidants and proteins, can also be used in the formulation of cosmetic and personal care products. Its use in creams and hair treatments is increasingly popular due to its regenerative and nourishing properties.

Benefits of Brewer’s Spent Grain Valorization

Valorizing brewer’s spent grain through Aurum Process solutions not only offers economic advantages but also has a positive environmental impact. Some of the key benefits include:

- Waste Reduction: By utilizing brewer’s spent grain, breweries significantly reduce the volume of waste they generate, contributing to less landfill waste and improving industrial waste management.

- Cost Savings: The utilization of this waste to produce valuable ingredients can generate additional income for breweries, reducing reliance on imported products and improving profitability.

- Sustainability: By using brewer’s spent grain as a resource, breweries align with the principles of the circular economy, promoting sustainability and respect for the environment.

Conclusion: The Future of Brewer’s Spent Grain is Innovation

Brewer’s spent grain represents one of the primary opportunities to improve sustainability and profitability in the brewing industry. Through the advanced technology of Aurum Process, this brewing by-product is transformed into a valuable resource that can be utilized across various industries. Technological solutions for processing brewer’s spent grain are clear evidence that innovation and the circular economy can work hand in hand to create a more sustainable future.

If you are part of the brewing industry or other sectors interested in industrial waste valorization, don’t hesitate to contact us to learn more about how our solutions can transform your production. Make brewer’s spent grain work for you and contribute to the sustainable future of the industry!